MoQuP-R: Monitoring Quality in Plastic Recycling

Projectpartners

- NTCP, Heerenveen (NL). Role: knowledge institute with industrial scale facilities.

- Maastricht University, Geleen (NL). Role: knowledge institute with pilot scale mechanical recycling.

- TNO, Utrecht / Geleen (NL). Role knowledge institute with existing quality and systemic models.

- LyondellBasell (D/NL). Role: recycler, polymer producer and converter.

- Danone (EU). Role: brand owner, packaging designer, converter.

- Graham Packaging (EU): Role: packaging designer, converter.

- Verpact (Afvalfonds), Leidschendam (NL). Role: extended producer responsibility organisation.

Background

In the plastic value chain there is only limited information available on the plastics in that chain to assess circularity and recyclability goals, especially the use of PCR in packaging as defined in e.g. the Packaging and Packaging Waste Regulation. For the stakeholder this leads to a situation where making choices on processes and technologies is difficult. Due to the large variety of plastic types and grades and types of applications, it is impossible to make a statement on the quality of a collected mixture of plastics related to the options for recycling of that mixture, especially when striving for high quality (or like-for-like) recycling. Some high-level averaged data is available for the composition of packaging waste related to outdated specification set by extended producer responsibility schemes.

A major challenge when it comes to monitoring the quality of plastics along the value chain, is that actual data is missing or very limited in a large number of steps along the process flow. Specification and standardisation of materials is common in certain industries like chemistry and pharma but is at this point only in an infancy state in plastic waste management.

Plastic recycling goals have not received focus on recyclate quality which is partly due to the way recycling rates have been calculated until 2022: any material stream coming out of a plastic sorting plant is considered recycled independent of the actual subsequent recycling process. This is now changing a bit with measuring the so-called washed and dried flake but is still far from complete and definitely not yet suitable for PCR quality prediction.

Goal of the project

In this project, we focus on the necessary quality monitoring tools and the application of existing models related to the prediction of recyclate quality in order to increase the use of PCR in packaging. An integral approach should allow adjustment along the circular value chain to improve PCR quality.

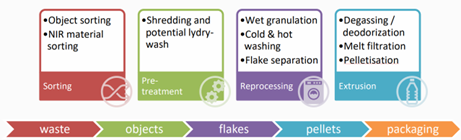

- The results will enable quality monitoring along the mechanical recycling chain for postconsumer plastic packaging waste by ways of a collection of suitable in-line characterisation technologies. We will make a distinction between the different relevant process steps in the recycling chain: sorting, pre-treatment, reprocessing, and extrusion. Along the chain the material stream will transform from packaging waste via flake and melt to pellet

- The results will enable and validate the use of existing recyclate quality predicting models (RQ and QMRP) with the acquired data from the monitoring methods. In addition, these models will be used to assess substitutability of virgin plastic by recyclate. We will assess the potential use of public models related to quality in plastic recycling for validation as well.

- The project results will set the stage for steering the recycling processes based on quality data along the chain. The in-line methods should enable application-based routing for certain materials along the recycling chain. Additionally, the order and settings of unit operations can be adjusted based on the collected quality data.

Short description of the activities

The project will be divided in four work packages (lead in brackets) to reach the goals of the project:

- Sorting, pre-treatment, and reprocessing (NTCP). Exploring and developing inline and at-line measurement methods in the mentioned processes at relevant scale. This includes NIR/RGB stream analysis, NIR moisture analysis, surface contamination analysis, particles in water and air, COD, BOD etc. in wastewater, flake analysis on material and colour. Showing the developed inline and at-line methods at industrial scale in the sorting, pre-treatment, and reprocessing steps.

- Mechanical recycling (UM-CCE). Exploring and developing inline methods in the extrusion process of recycling. This includes inline rheometry, Raman spectroscopy, and gas chromatography for NIAS and IAS. Showing the developed inline and at-line methods at industrial scale in the extrusion steps.

- Model application (UM-CCE). Using existing, mainly public, models (e.g. RQ, QMRP, RecyQMeter) around the prediction of recyclate quality using the data collected in the project.

- Knowledge dissemination (NTCP). Making the developed methods and findings available to the community.

- Technical project lead (NTCP). Leading the technical content of the overall project. The administrative part will be outsourced.

Results

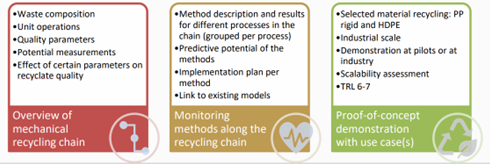

To reach the set objectives, we have identified three separate set of results in the project as shown in the scheme below.